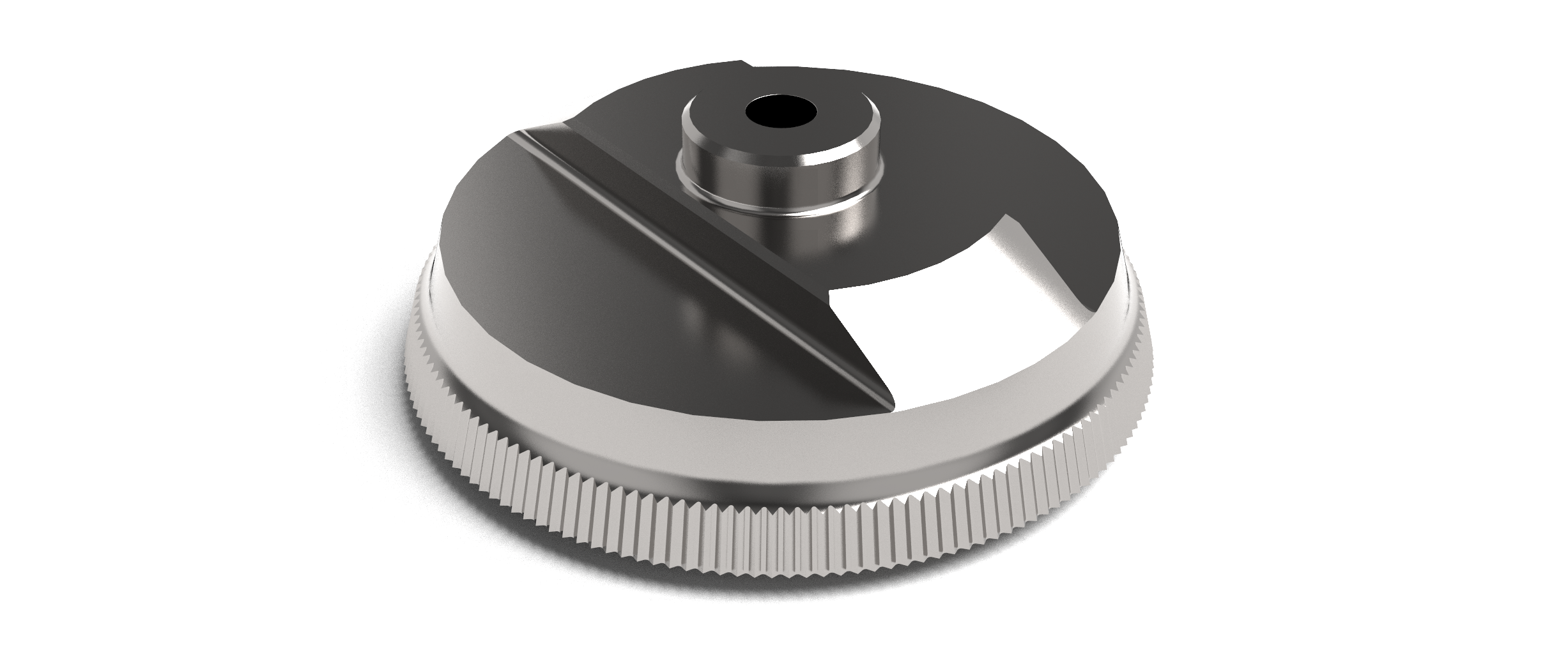

Cutting Wheel coarse serrated

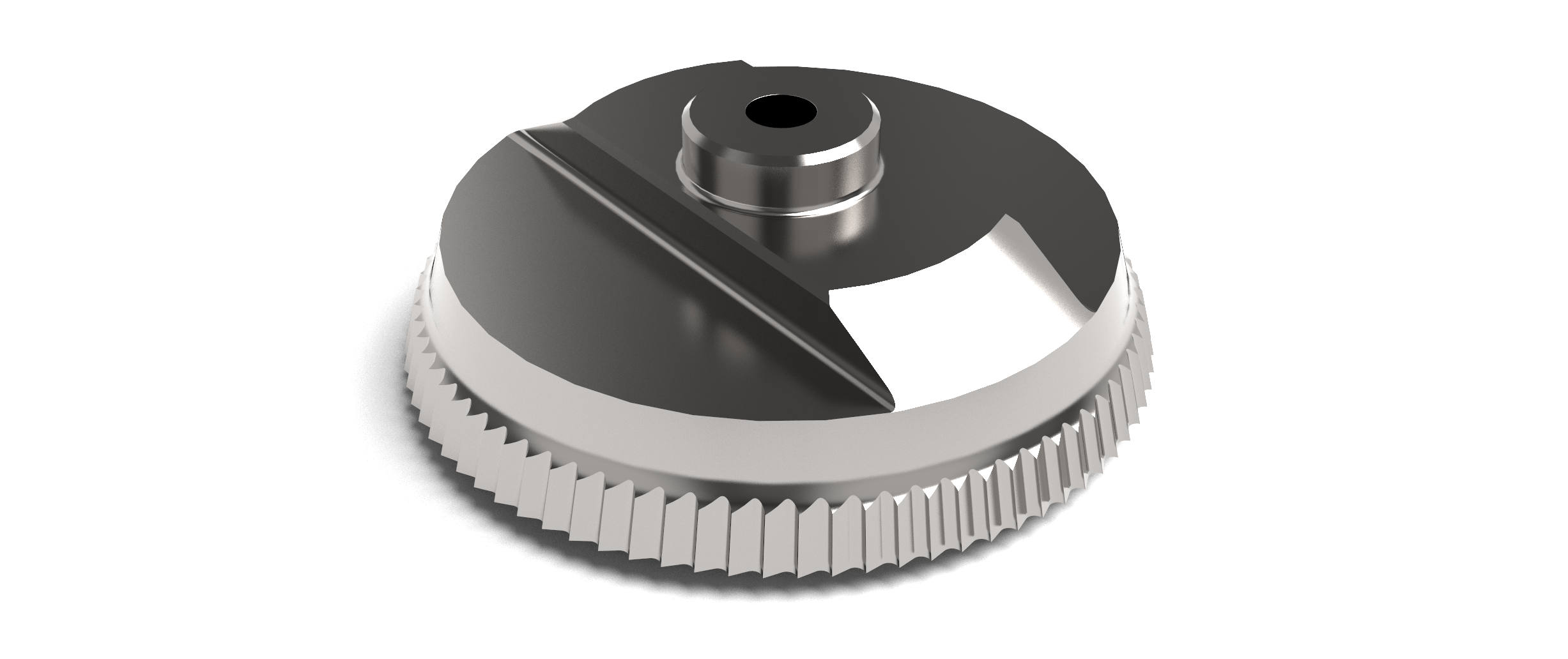

Cutting Wheel standard serrated

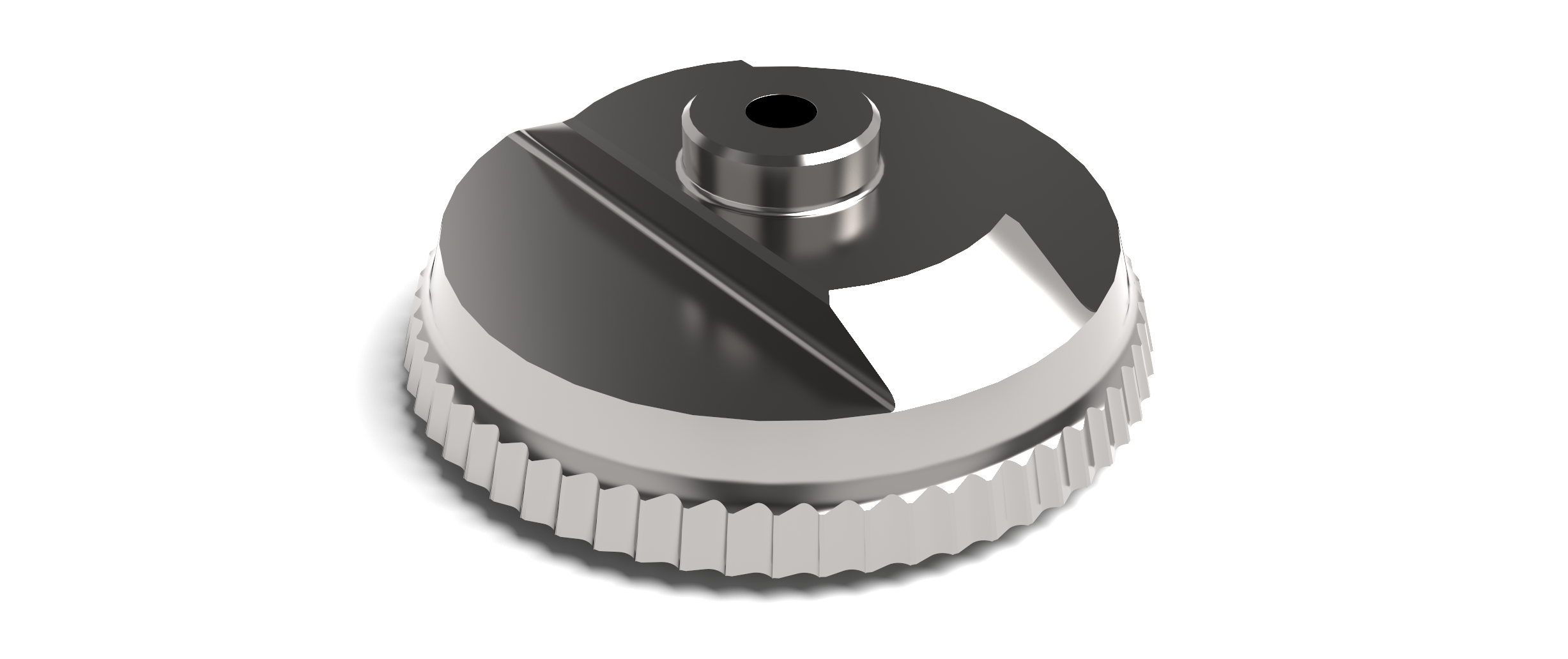

Cutting Wheel fine serrated

Cutting Wheel standard serrated "Chipper"

Cutting Wheel fine serrated "Chipper"

Cutting Wheel coarse serrated "Chipper"

Cutting Wheel extra-coarse serrated

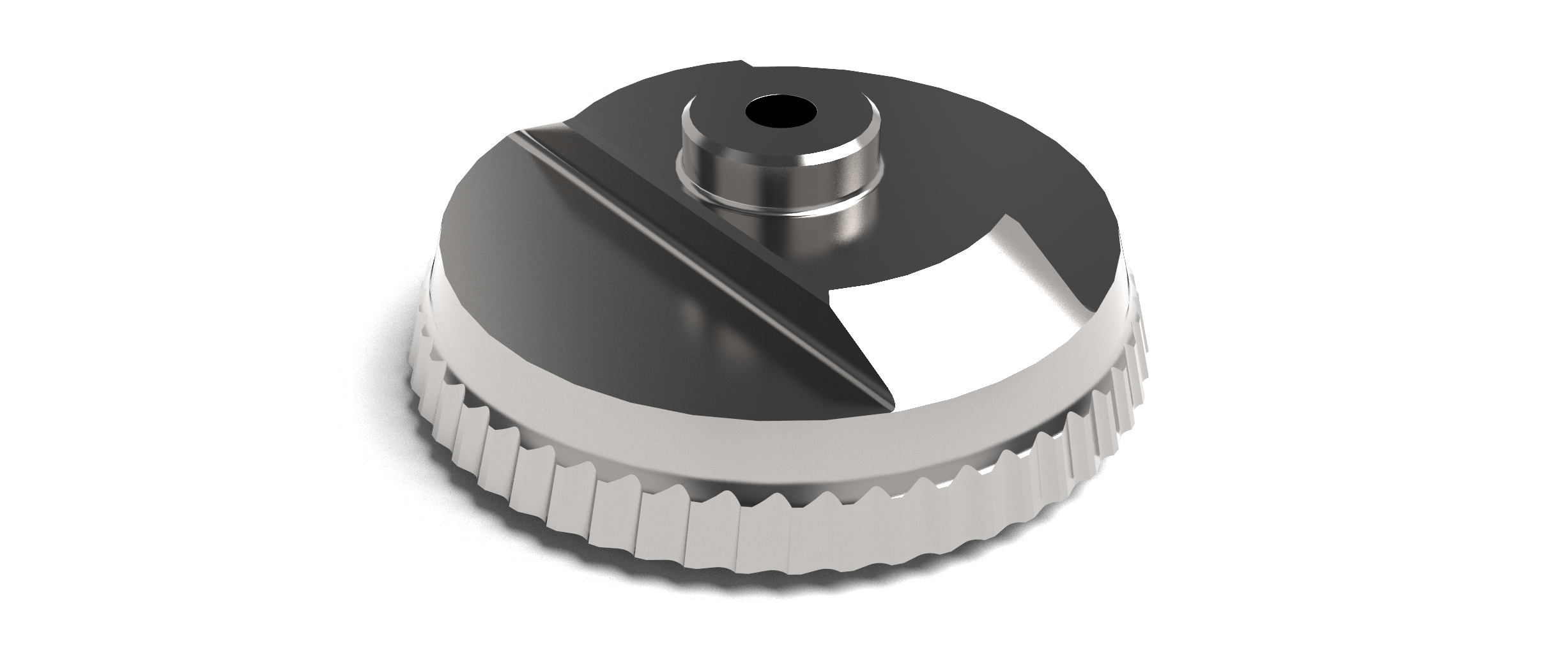

Cuttingwheel, medium serrated

Choose the type of cutter to suit your type of work

The standard serrated cutter can be used for most jobs, but the machine can be fitted with coarse serrated or fine serrated cutters as required. Coarser teeth are used for larger bevel widths in heavy material and fine teeth are intended for use in lighter work with smaller bevel widths up to 15 mm. Cutters are made from hardened alloy tool steel.

High performance bevel

1. Maximum bevel is 25 mm and is possible to achieve in plate with a tensile strength of 390 N/mm².

2. Maximum tensile strength to be beveled is 690 N/mm² and gives a bevel of 13 mm.

Fine-toothed cutter gives the smoothest cut. Difficulties, however, could arise with feeding, when bevelling harder or tougher materials, especially if the bevel is deep. In such cases a coarse-toothed cutter has to be used.

Standard cutters are recommended for materials with a tensile strength below 550 N/mm².

High tensile “chipper” cutters are recommended for materials with a tensile strength between 550 N/mm² and 690 N/mm²).

Cutting Wheels for Pullmax X91 - X93 - X97

161.505.85 Cutting Wheel Fine serrated

Typ C

160 Teeth

.

161.504.85 Cutting Wheel standard serrated

Typ B

80 Teeth

161.503.85 Cutting Wheel coarse serrated

Typ A

60 Teeth

198.724.01 Cutting Wheel medium serrated

104 Teeth

Cutting Wheels for Pullmax X91 - X93 - X97 "Chipper"

Standard cutters are recommended for materials with a tensile strength below 550 N/mm².

High tensile “chipper” cutters are recommended for materials with a tensile strength between 550 N/mm² and 690 N/mm²).

163.704.01 Cutting Wheel fine serrated "Chipper"

160 Teeth

163.703.01 Cutting Wheel standard serrated "Chipper"

80 Teeth

163.705.01 Cutting Wheel coarse serrated "Chipper"

60 Teeth

198.026.01 Cutting Wheel extra-coarse serrated "Chipper"

51 Teeth

• PULLMAX Ges.m.b.H.

• Kastelicgasse 5

• A-3100 St.Pölten

• Austria

• Tel. +43 (0)2742-310 255

• info@pullmax.at

• www.pullmax.at

Copyright © 1999-2023 PULLMAX Ges.m.b.H.

All Rights Reserved

PULLMAX Ges.m.b.H.

Kastelicgasse 5

A-3100 St.Pölten

Austria

Tel. +43 (0)2742-310 255

info@pullmax.at

www.pullmax.at

Copyright © 1999-2023 PULLMAX Ges.m.b.H.

All Rights Reserved