The X97 beveling machine functions basically the same way as roller shears, utilizing only one cutter. The shearing action actually feeds the work piece automatically through the machine.

The method can be used for X, V, Y and K-form joints.

The degree of bevel angle is infinitely variable from 25° up to 55°.

Motorized and adjusted by push-button control, a high degree of accuracy is achieved and is easily read on a graduated dial.

The capacity of the machine covers up to 50mm (2″) thick plate and 25mm (1″) width of bevel in normal steel plate rated at 400N/mm² (57,000 psi) tensile strength.

The speed of bevelling is between 1,5 and 3,1m/min (6 and 12 ft./min.), depending on the width and degree of angle for the bevel being produced.

Since the bevel is achieved without heat, the cut surface is clean and unaffected by thermal stress.

This makes the X97 suitable for certain grades of stainless steel as well as aluminium.

The groundwork for high-quality welded joints is carried out at the preparation stage – when the edges of the workpieces are beveled.

It is important that the bevel is uniform along the full length of the edges to be welded and this is particularly important when using automatic welding where the volume of the weld is constant.

Another important factor is that the beveling must not cause deformation of the pieces to be welded.

If they are bent or buckled, it becomes difficult to keep the gap width constant along the whole length of the joint.

If these requirements for dimensional accuracy and freedom from deformation are met, then the conditions are right for making a high-quality weld. Cleanliness of the edges of the work and freedom from chemical action are,of course, also advantageous to the production of good welds.

X-97 beveling machines produce a result which meets all these basic requirements.

The Pullmax X97 offers superior versatility.

With motorized adjustment of bevelling angles, choice of cutters, stationary or suspended operation, a full range of accessories, and pinpoint accuracy for a variety of shapes and sizes of work pieces.

The PULLMAX X97 fits the work piece rather than forcing the work piece to fit the machine.

The Pullmax X97 offers superior versatility.

With motorized adjustment of bevelling angles, choice of cutters, stationary or suspended operation, a full range of accessories, and pinpoint accuracy for a variety of shapes and sizes of work pieces.

The PULLMAX X97 fits the work piece rather than forcing the work piece to fit the machine.

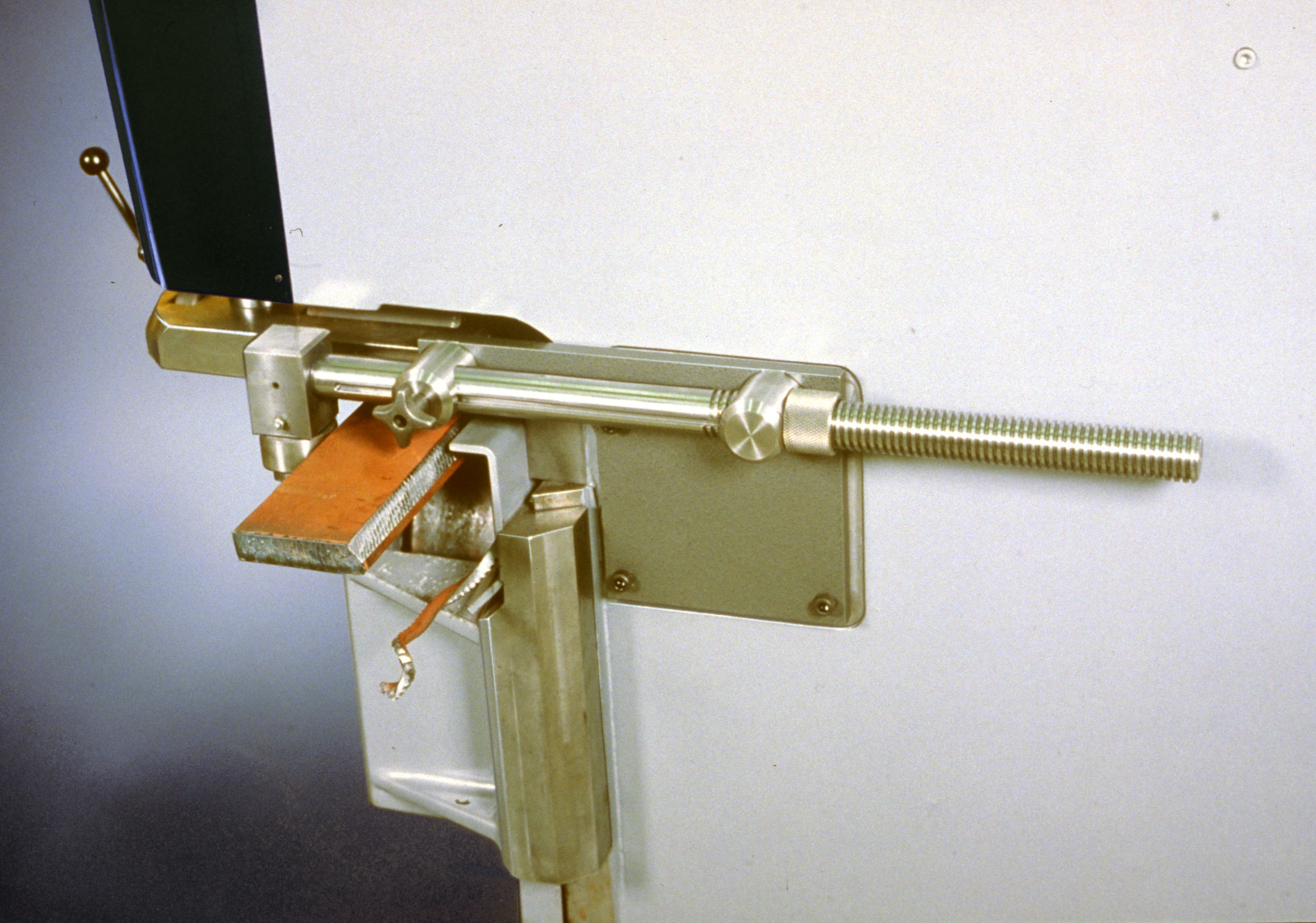

When narrow steel strips and flat bars, or similar material is to be beveled, there is sometimes a tendency for the width of the bevel to increase towards the end.

A guide can be provided for use with the X-97 on workpieces with parallel edges.

The PULLMAX X97 fits the work piece rather than forcing the work piece to fit the machine.

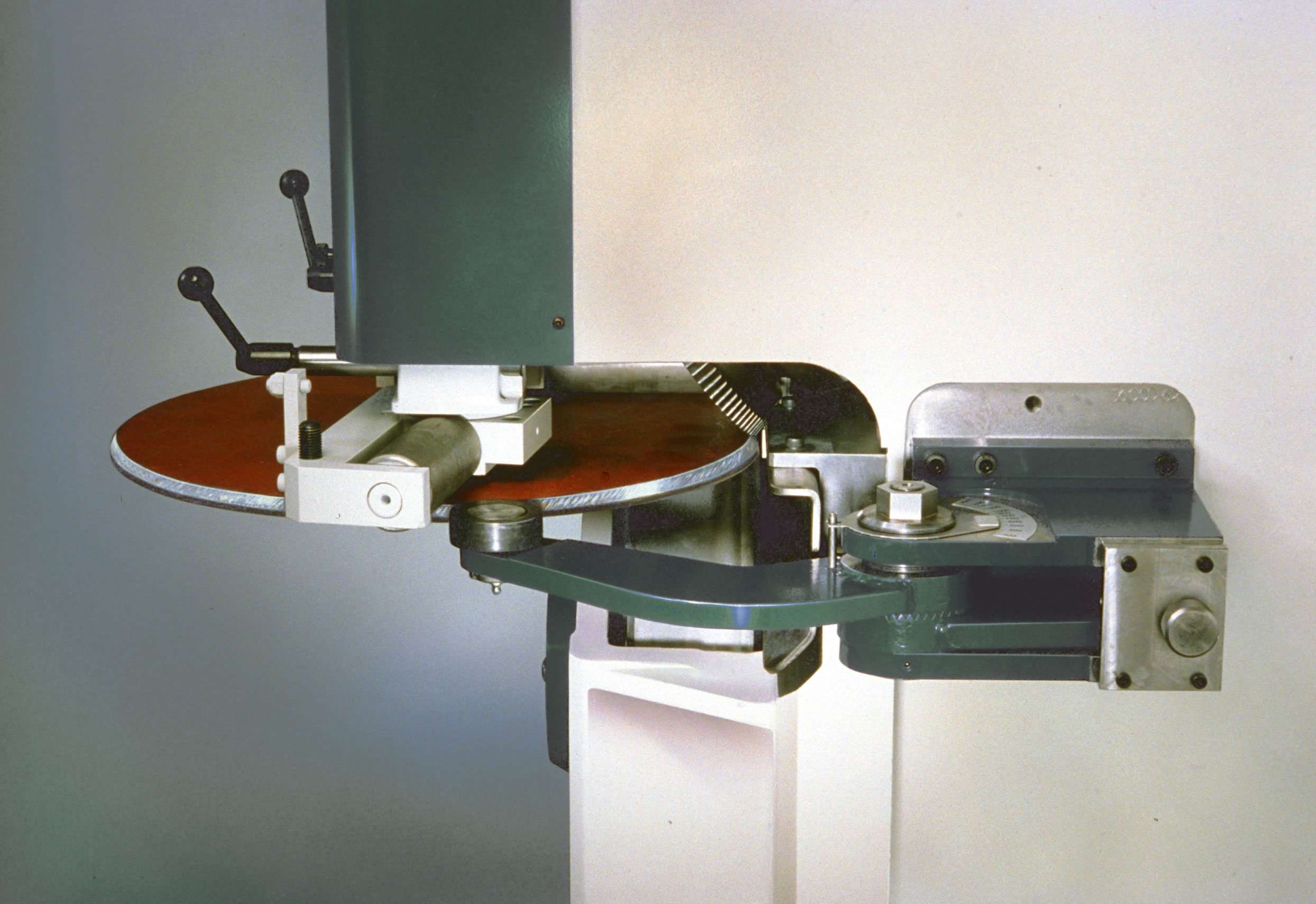

When fitted with a circular control device the machine can be used for external beveling of circular workpieces, with diameters down to 450 mm. The device consists of a guide roller and adjuster. Settings are made on a graduated scale.

The position of the machine can be adjusted to suit the shape, size and weight of the workpiece. It can stand in a stationary position, or it can be suspended for movement either in ordinary position or upside-down. If the machine is suspended, it can be made to move itself along the workpiece, instead of feeding the workpiece through the machine.

When narrow steel strips and flat bars, or similar material is to be beveled, there is sometimes a tendency for the width of the bevel to increase towards the end. A guide can be provided for use with the X-97 on workpieces with parallel edges.

The PULLMAX X97 fits the work piece rather than forcing the work piece to fit the machine.

• PULLMAX Ges.m.b.H.

• Kastelicgasse 5

• A-3100 St.Pölten

• Austria

• Tel. +43 (0)2742-310 255

• info@pullmax.at

• www.pullmax.at

Copyright © 1999-2025 PULLMAX Ges.m.b.H.

All Rights Reserved

PULLMAX Ges.m.b.H.

Kastelicgasse 5

A-3100 St.Pölten

Austria

Tel. +43 (0)2742-310 255

info@pullmax.at

www.pullmax.at

Copyright © 1999-2025 PULLMAX Ges.m.b.H.

All Rights Reserved

| Cookie | Duration | Description |

|---|---|---|

| cookielawinfo-checkbox-analytics | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Analytics". |

| cookielawinfo-checkbox-functional | 11 months | The cookie is set by GDPR cookie consent to record the user consent for the cookies in the category "Functional". |

| cookielawinfo-checkbox-necessary | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookies is used to store the user consent for the cookies in the category "Necessary". |

| cookielawinfo-checkbox-others | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Other. |

| cookielawinfo-checkbox-performance | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Performance". |

| viewed_cookie_policy | 11 months | The cookie is set by the GDPR Cookie Consent plugin and is used to store whether or not user has consented to the use of cookies. It does not store any personal data. |